Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: GYKM | Place of Origin: China |

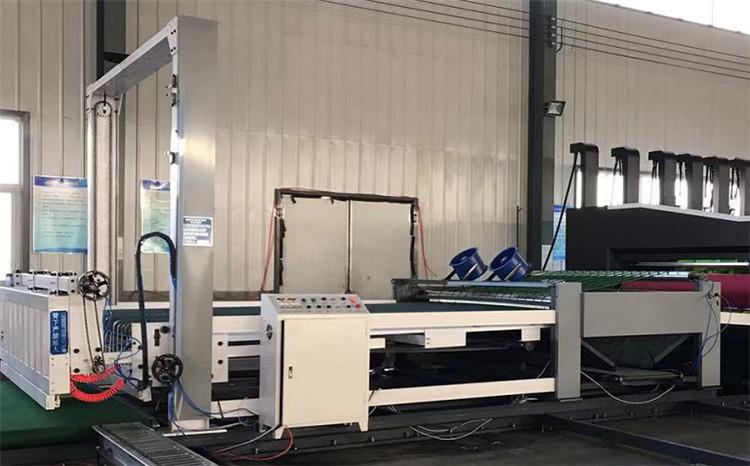

GYKM- High speed flexo printing slotting rotary die cutting with vibrating stacker machine

Maximum Paper Feeding size: 920×2200mm 1200×2400mm 1400×2600mm

(We can custom-made the machine size for you) Machine running speed: 150~280 pieces/minutes

1. The main wall body: After Japan mitsubishi five-sided machining center processing.

2. Transmission gear: High precision grinding teeth.

3. Printing roller: 45# steel rolling welding, computer dynamic balance correction, grinding and hard chromium plating.

4. Anilox roller: Dynamic balance correction

5. Electrical part: Siemense, Scheigher, Delta, Fatek,

6.Lead edge feeder unit. vacuum sucking feeding cardboard

7. Auto ink circulation system

8. Fully electric control slotting creasing slitting knives which is easy to change order.

9.The gear of the machine: Auto lubrication with oil

10.Machine body thickness:60mm

11.Automatic separate, pneumatic lock up.

Adsorption lead edge feeding system

1) The lead edge feed mechanism can minimize the jamming in the paper feeding process at the greatest extent.

2) The suction blower assists the feeding of paper. to ensure that the curved paperboard is smoothly fed in. The air volume can be adjusted according to the size of the paperboard, and the vacuum suction force of the paperboard can be ensured to the utmost so as to make the paper feeding more accurate.

3) The front dam-board and the rear dam-board adopt manual adjustment gaps, and the left and right side dam-board of the paper feed are electrically adjust gaps.

4) The feed wheel is made of polyurethane material, which has high friction and long service life.

5) Suitable for three, five, seven layers of corrugated cardboard, including E-flute corrugated cardboard

6) Paper counter, setting, display the production quantity.

7) Equipped with a dust extraction mechanism (dust extraction brush and vacuum suction fan) to effectively remove paperboard surface impurities and improve, to improve printing quality.

Printing unit

Slotting unit (Computer adjustment)

Rotary Die cutting unit

Automatic vibrating stacker unit