Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: Automatic Flute | Place of Origin: China |

Automatic Flute Laminating Machine

High Speed Automatic Corrugated Cardboard Flute Laminating Machine

Carton Board Making Machine

1. The vacuum suction-type feeding system can lead the paper accurately into the machine;cycle stacking planes in a state of non-stop the next batch of paper stack well, so that more efficient.

2. Using suction feeding automatic of bottom sheet, according to the main machine operating speed, continuous automatic tracking.

3. The machine operation is stable, surface paper with corrugated paper joint very Accurate. The corrugated paper never pull ahead, surface paper's location is easy adjust.

4. Machine uses touch-screen/PLC/servo motor control system, the circuit system is stable, and can automatically display the failure alarm.

5. Automatic gluing, and the glue can be used circulatory, avoid glue waste.

6. Roller design scientifically, avoid glue fly out when the speed is high.

7. Pressure rollers adopt unilateral adjustment, convenient and fast.

8. Rocker controls wash roller's fluctuation, easy cleaning.

9. Counter designs scientifically, easy recording the amount you have been worked.

Feida Feeding

Independently develop a powerful FEIDA paper with precoded paper device to reduce downtime and improve work efficiency

The machine adopts frequency conversion to regulate speed. PLC centralized control, module conversion, operation control standard

After balancing treatment and testing, the steel roller, coupled with the tightening assembly process, effectively improves the mechanical stability.

Double servo control is adopted to realize the timeliness and accuracy of the base paper to the front gauge, so as to ensure the accuracy of the machine under the operating condition

The machine is suitable for 150-450gsm paper, A B C D E F wave and three and five layers cardboard (the maximum thickness is less than 10mm)

Specification

|

Model |

LT-1300D |

LT-1450D |

LT-1600D |

|

Max laminating size |

1100mm×1300mm |

1100mm×1450mm |

1100mm×1600mm |

|

Min laminating size |

400mm×400mm |

400mm×400mm |

400mm×400mm |

|

Max working speed |

6000 Pecs/hour |

6000 Pecs/hour |

6000 Pecs/hour |

|

Laminating precision |

≤±1.5mm |

≤±1.5mm |

≤±1.5mm |

|

Power |

14kw |

14kw |

14kw |

|

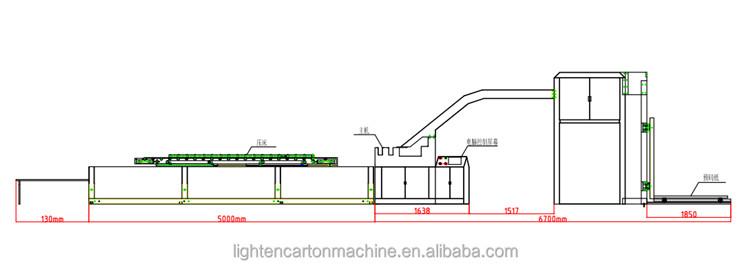

Dimensions |

12m×2.2m×2.5m |

12m×2.35m×2.5m |

12m×2.5m×2.5m |

|

Net weight |

About4.5t |

About5t |

About5.5t |